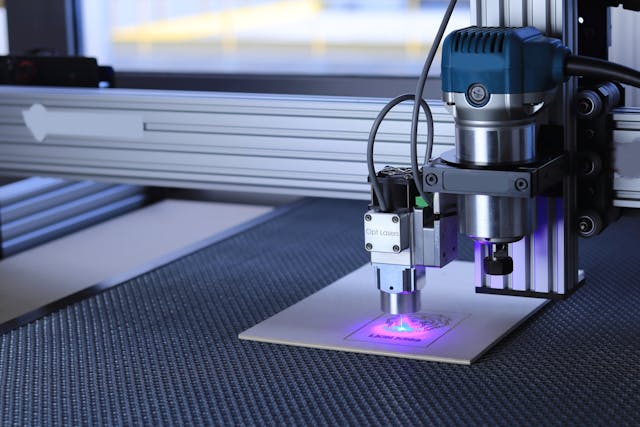

In the field of precision manufacturing, laser cutting has become a game-changer, revolutionizing the way materials are molded and cut in a variety of industries. With this technique, materials can be sliced, engraved, or marked quickly and accurately using a powerful laser beam. Laser cutting has many benefits over traditional cutting techniques, ranging from the manufacturing of metal to the production of complex shapes in wood and plastics.

The Science Behind Laser Cutting

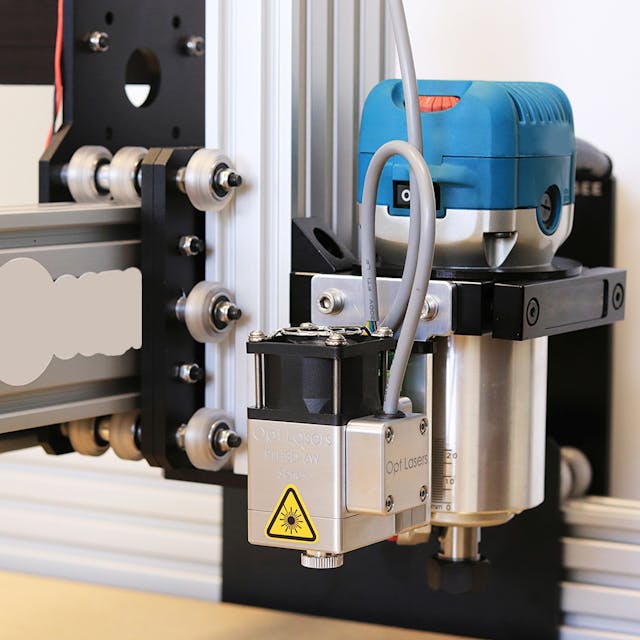

At its core, laser cutting involves directing a focused beam of light, typically from a CO2, fiber, or crystal laser, onto a material. The laser beam melts, burns, or vaporizes the material along a predetermined path, creating precise cuts or engravings. The process can be controlled by computer numerical control (CNC) systems, which translate digital designs into physical objects with remarkable precision.

Key Advantages of Laser Cutting

- Precision and Accuracy: One of the primary benefits of laser cutting Melbourne is its unparalleled precision. The laser beam can cut materials with a tolerance as tight as 0.001 inches, allowing for intricate designs and detailed work that traditional methods cannot achieve.

- Speed and Efficiency: Laser cutting is a fast process, especially when dealing with complex designs. The ability to automate the process through CNC systems further enhances efficiency, reducing production time and increasing throughput.

- Minimal Material Waste: The precision of laser cutting means less material waste. Traditional cutting methods often require extra material to account for inaccuracies, but laser cutting’s exactness reduces this need, leading to cost savings and more sustainable manufacturing practices.

- High-Quality Finishes: The clean edges and smooth finishes produced by laser cutting eliminate the need for secondary finishing processes, such as sanding or deburring. This results in higher-quality end products and saves additional labor costs.

Applications of Laser Cutting

Laser cutting’s flexibility and precision have made it indispensable in various industries:

- Manufacturing and Fabrication: In manufacturing, laser cutting is used to create components for machinery, automotive parts, and aerospace structures. Its precision is crucial for ensuring the integrity and performance of these high-stakes applications.

- Art and Design: Artists and designers leverage laser cutting for creating intricate patterns, custom jewelry, and decorative items. The technology enables the realization of complex artistic visions with exactness and repeatability.

- Medical Devices: The high degree of accuracy ensures that these devices function correctly and safely within the human body.

- Signage and Packaging: The advertising and packaging industries use laser cutting to create custom signs, packaging prototypes, and display materials. The technology allows for rapid prototyping and customization to meet client needs.

Laser cutting has revolutionized the precision manufacturing landscape, offering unmatched accuracy, versatility, and efficiency. Its applications span numerous industries, from heavy manufacturing to fine arts, making it a pivotal technology in modern production processes. As advancements continue to emerge, laser cutting is set to become even more integral to innovative and sustainable manufacturing solutions.